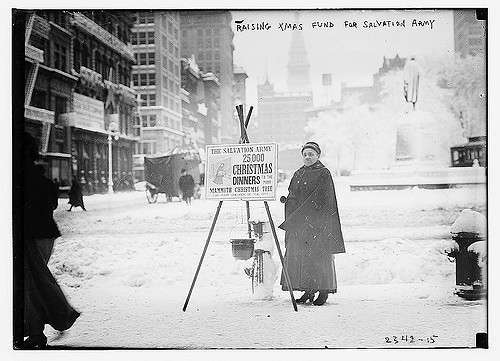

The small bells rung by Salvation Army soldiers during the Christmas holidays are all made in Connecticut.

So is the small bell that rings when Clarence the angel gets his wing in the 1946 film It’s a Wonderful Life..

And every business day, the New York Stock Exchange opens to the ringing of a small bell made in Connecticut.

They were all made by Bevin Brothers of East Hampton, Conn., the oldest maker of small bells in the United States.

Bevin Brothers is also the last surviving bell maker in Connecticut. The state that produced the Frisbee, the lollipop, the can opener, the box clock and the Mickey Mouse watch also once made nearly every small bell in the United States and Canada.

The Bevin Brothers Bell Shop.

During the 19th century, nine out of 10 small bells were made in Connecticut, and most of them were made in East Hampton.

Why East Hampton?

It all started in 1808, when a soldier’s son and his indentured servants moved to East Hampton.

Small bells had been made in Connecticut since the colonial era. Initially, blacksmiths made iron cow and hand bells for farm and other purposes before specialists—mainly in sleigh bells—emerged in the early 19th century.

Sleigh bell production may have started with Capt. William Barton in the 1770s in Wintonbury (now Bloomfield), Conn. By 1800 James North, Jr., and Joseph Shipman had formed a partnership in New Britain to make sleigh bells. In 1803 Seth North, a brother of James, Jr., became sole owner and operated the foundry until 1840.

In 1808 William Barton, the son of the captain, moved to East Hampton (Chatham until 1915) and began making hand and crotal (sleigh) bells. His main achievement was to rediscover a sand-core casting process for a one-piece bronze bell with the pellet (rattle) inside instead of using a well-known two-piece soldering method that took more time to complete. His sleigh bells, ranging in size from one to four inches in diameter, could have various finishes, often had his initials and were sold by weight or by their amount and quality.

Barton left East Hampton for Cairo, N.Y., around 1826 to again cast bronze sleigh bells, stayed about 20 years, and then retired back in East Hampton. Several descendants carried on the bell business there until 1888, when the last Barton-connected company moved to Indiana. Notably, Jason Barton, a son of William, developed a cost-effective alternative to polishing each bell on a lathe by tumbling them in barrels of sand.

Apprentices

William Barton did not patent his method of making small bells. He believed that his knowledge of the craft should be shared with his many apprentices. Among them were William and Abner Bevin, who were indentured to Barton in the late 1820s.

The Bevin brothers, now including Chauncey and later Philo in 1838, established their bell factory in 1832 in East Hampton. The brothers made mostly sleigh bells that, over time, came to include more than twenty different sizes of mainly round-shaped or globe bells and, to a lesser extent, bevel or band bells that usually had only one slit (“throat”). They also produced cow bells, kettles and coffee mills.

New Kinds of Small Bells

As roads steadily improved and became more crowded with sleighs throughout the 19th century, the demand for sleigh bells increased. More than ever, they were needed as a warning for approaching pedestrians and other vehicles. Concomitantly, more competitors entered the market for small bells, especially in East Hampton.

Sleigh bell production concentrated in East Hampton as it offered several advantages for the new makers of small bells: inexpensive waterpower; access to roads, waterways and railroads for obtaining raw materials and distributing the bells; shared knowledge of production methods and marketing strategies—especially in the early decades. The new bell makers also had a readiness to develop newer types of small bells. An estimated 30 firms operated at some time during the century and by 1900 had made, perhaps, 90 percent of all small bells in the U.S. and Canada.

East Hampton, Conn., had so many foundries making small bells that it earned the nickname BellTown.

Competition

Nevertheless, competitive conditions had intensified in the last decades of the century, which forced many firms to close. By 1906 only six longtime firms remained: Bevin Brothers, East Hampton Bell Co. (started in 1851), D.W. Watrous (1865), Gong Bell Manufacturing Co. (1866), Starr Brothers Bell Co. (1882), and the N.N. Hill Brass Co. (1889).

Other sleigh bell makers also operated outside of East Hampton. These firms included: the Taylor Manufacturing Co. of New Britain (started around 1872), known for its Russian sleigh bells; the American Ring Co. of Waterbury, whose single and multiple-slitted stamped sleigh bells of Maj. George W. Tucker were probably produced around 1872; and the Chapman Manufacturing Co. of Meriden (1881), which made chime sleigh bells. The American Ring Co. became part of the Plume & Atwood Manufacturing Co. of Waterbury in 1894. The Chapman Co. suspended business in 1900 and the fate of the Taylor Co. is unclear.

Cars and Wars

The advent of the automobile in the late 19th and early 20th centuries drastically reduced demand for sleigh bells. The competing firms responded through innovations in production techniques and their product lines in an effort to stay in business.

N.N. Hill revolutionized production by stamping sleigh bells from sheet metal around 1885, as an alternative to the old casting process, which significantly lowered its costs.

After 1900, hydraulically operated forging machines became common in bell making, especially for toys. The Gong Bell firm started by producing a doorbell based on a gong, but became the first company in 1872 to make bell toys with its initial product—‘revolving chimes’ on cast iron wheels. In the early 1900s it created a foot-operated automobile bell, a precursor of the horn. The Watrous firm, starting in the early 1900s, also began making bell toys that often used cast iron figures to strike a bell or chime. The Gong Bell Company acquired Watrous in 1923, but dissolved it in 1927.

Over the next several decades the East Hampton firms had to contend with the Great Depression and metal restrictions during World War II and the Korean Conflict. They also dealt with foreign competition—especially from Germany and Japan. All of them, with one exception, finally succumbed to economic pressures.

Bevin Bells

The East Hampton Bell Co., which had become a subsidiary of Bevin Brothers, dissolved in 1943. The Starr Brothers firm went bankrupt in 1954. N. N. Hill could no longer compete by 1960, followed by the Gong Bell Company a year later. Gong Bell, which also had become a subsidiary of Bevin Brothers, had long been successful with its line of toy telephones that it initially invented in 1921. However, it failed to convert production from metal and wood to plastic.

Since 1961 Bevin Brothers has remained—despite a devastating fire on May 27, 2012—the oldest small bell producer in America. Before the fire the company produced over one million small bells a year in more than 100 varieties, including its claim of the first bicycle bells. Currently, it still produces its traditional sleigh, cow and hand bells, but custom imprinting of small bells for businesses, schools, clubs, and athletic events represents the largest share of its activity.

* * *

The Christmas holiday actually began in ancient Rome — and so did Italian cookies. The New England Historical Society’s new book, 24 Historic Italian Christmas Cookie Recipes, tells you how to make those delicious cookies. It also bring you the history of the Italian immigrants who brought them to New England. Available now on Amazon; just click here.

About the author: Edward T. Howe is Professor of Economics, Emeritus, of Siena College near Albany, N.Y He has written academic articles about the bell industry in New York, incorporated villages in New York and Vermont, and nationwide taxation of the electric utility industry. This story was updated in 2022.

Images: Bevin Brothers Bell Shop by By Unknown author – Historic American Engineering Record, Public Domain, https://commons.wikimedia.org/w/index.php?curid=40743178.

2 comments

Terrific article. As a former “neighbor (Cobalt)” of East Hampton, CT, I enjoyed a history I hadn’t known before.

[…] in Vermont, and nationwide taxation of the electric utility industry. He has also written about the small bells made in Connecticut for the New England Historical […]

Comments are closed.